Select your language

At it-neX, we're bringing the future of maintenance to you – today!

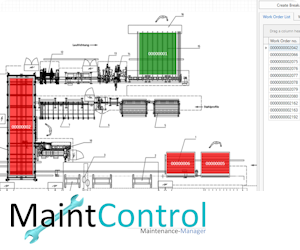

Our cutting-edge solutions like MaintMan®, MaintMobile®, MaintRequest®, and MaintControl® are transforming the way you handle maintenance and management for facilities, vehicles, building systems, fire protection, test equipment and more.

With over 40 years of experience and a global customer base, we know what matters most: efficiency, user-friendliness, and flexibility. Our software covers everything – from repairs and troubleshooting to a comprehensive ticketing system. This means you can effortlessly manage your maintenance tasks anytime, anywhere.

Discover how our products can revolutionize your processes. Welcome to it-neX – where innovation meets experience.

Email: info@it-nex.com

Phone: +49 (7131) 203335 0

Email: info@it-nex.com

Mon to Fr: 8.00am to 17.00pm

Request For Call Back

Why MaintMan®

it-neX is committed to developing innovative and customized maintenance programs that revolutionize our customers' maintenance processes. By combining technical expertise, extensive industry knowledge and a clear focus on customer satisfaction, we have been setting new standards in the maintenance industry for more than 35 years.

EN-US

EN-US  DE

DE